Page 26 - SyI Quarterly - Q3 and Q4 Edition 2023

P. 26

Know your Institute

Know your Institute

Industrial Safety and Protective Security: A Cheese

& Onion Flavour

By Frank Cannon CSyP FSyP

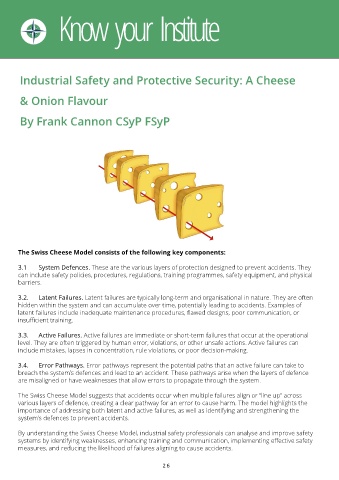

The Swiss Cheese Model consists of the following key components:

3.1 System Defences. These are the various layers of protection designed to prevent accidents. They

can include safety policies, procedures, regulations, training programmes, safety equipment, and physical

barriers.

3.2. Latent Failures. Latent failures are typically long-term and organisational in nature. They are often

hidden within the system and can accumulate over time, potentially leading to accidents. Examples of

latent failures include inadequate maintenance procedures, flawed designs, poor communication, or

insufficient training.

3.3. Active Failures. Active failures are immediate or short-term failures that occur at the operational

level. They are often triggered by human error, violations, or other unsafe actions. Active failures can

include mistakes, lapses in concentration, rule violations, or poor decision-making.

3.4. Error Pathways. Error pathways represent the potential paths that an active failure can take to

breach the system’s defences and lead to an accident. These pathways arise when the layers of defence

are misaligned or have weaknesses that allow errors to propagate through the system.

The Swiss Cheese Model suggests that accidents occur when multiple failures align or “line up” across

various layers of defence, creating a clear pathway for an error to cause harm. The model highlights the

importance of addressing both latent and active failures, as well as identifying and strengthening the

system’s defences to prevent accidents.

By understanding the Swiss Cheese Model, industrial safety professionals can analyse and improve safety

systems by identifying weaknesses, enhancing training and communication, implementing effective safety

measures, and reducing the likelihood of failures aligning to cause accidents.

26